Inline Filling Systems Olive Oil Filler

Inline Filling Systems Olive Oil Filler

Location:California

Description

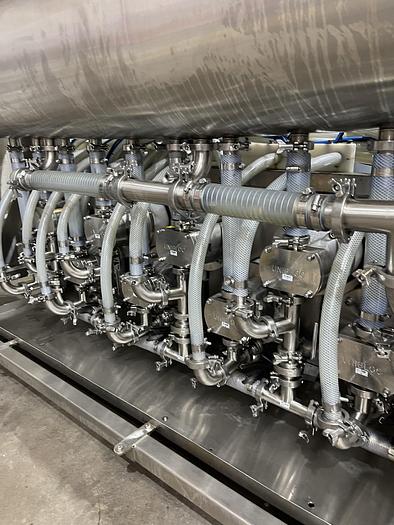

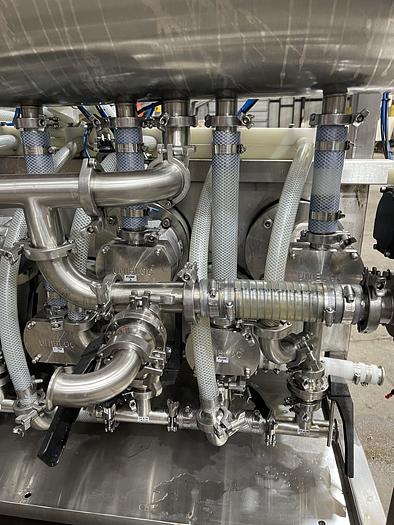

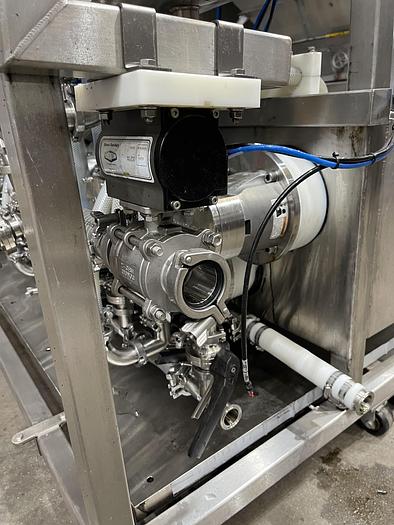

Inline Filling Systems Filler

Made in USA, Filling 1-250 Liter Plastic & Aluminum Bottles.

Last used for filling Olive.

LINE SPEED When analyzing the production speeds or capabilities of your current system, your first task is to identify the slowest machine or process on your line. These slowest process points will determine your actual line speed. If personnel are used in a line processing function (removing filled containers, visual inspection, etc.) they must be examined as a processing point. Under most circumstances, the maximum continuous container handling capability of a person is 8 to 12 bottles per minute. Once your slowest bottle per minute capability is determined, it is relatively simple to set a conveyor line speed that will keep up with your true line capabilities. A useful formula for computing conveyor speed is shown below. Bottles per minute 1.3 = Conveyor line speed If your peak BPM is 50 Bottles per minute, your conveyor does not have to exceed 42 Feet per minute. Once your conveyor speed is determined, follow our SEQUENCE OF SET to complete your application analysis. SUMMARY IFS have found that the cost of your packaging line is miniscule compared to lost revenue due to misapplied machines, poorly trained personnel, and inadequate setups. A common example: One poorly adjusted set of rails at a transfer point knocks over bottles about once an hour. This is often looked at as the loss of a few bottles of product. Your actual cost per day is 10 to 20% of your total production. It’s not the 12 spilled containers that cost you. It is the 10 minutes it takes to clean up, then restart the line after each spill.

OFFSITE ITEM

Specifications

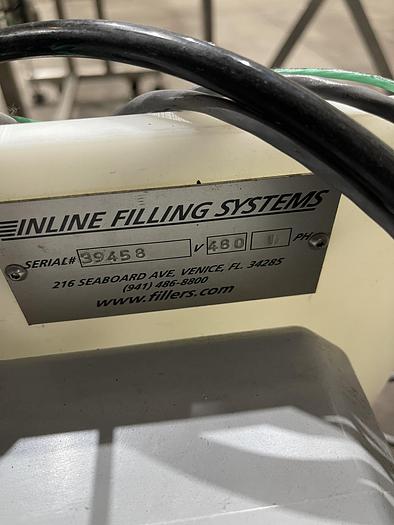

| Manufacturer | Inline Filling Systems Olive Oil Filler |

| Condition | Used |

| Serial Number | 39458 |

| Stock Number | OFF |